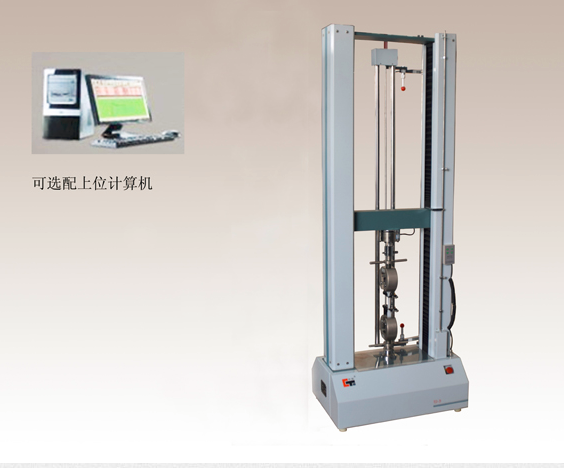

As we all know, electronic tensile testing machines are generally indispensable testing equipment such as scientific research institutes, commodity inspection arbitration institutions, universities and colleges, as well as packaging, building materials, petrochemical, and aviation industries. Electronic tensile testing machine is mainly used for testing various physical and mechanical properties of rubber, plastic sheet, pipe and other materials. So what do you know about the need for an experimental environment for electronic tensile testing machines?

What is the need for an experimental environment for electronic tensile testing machines?

Usually, the test environment of the electronic tensile tester determines the accuracy of the test data and the integrity of the test equipment. Therefore, in order to obtain accurate test data, the relevant environmental requirements of the electronic tensile tester should be strictly observed. Generally speaking, they can be divided into six major categories. This is only a general introduction. When users use electronic tensile testing machines, they must follow the relevant standards of the relevant materials. The

tensile testing machine for sale1, the laboratory space must be greater than the size of the electronic tensile testing machine itself, like vertical electronic tensile testing machine models, such as the test space of 3 meters ring stiffness testing machine, in order to facilitate the test and placement, the laboratory space should at least 4 meters; and for horizontal electronic tensile testing machine products, because of its unique test space requirements, the laboratory space will reach tens of meters. The

2, the laboratory thermometer humidity must be controlled within a certain range, high test temperature, it is easy to test equipment, motors, sensors and other failure frequency increase, and if the indoor humidity is too high, it will lead to equipment life Rust, in short, if there is no special requirement, all material mechanics testing standards are specified in the range of room temperature 10 °C -35 °C, relative humidity is not more than 80%. The

3. The ground of the position where the electronic tensile testing machine is installed must be flat and stable. If it is not flat, then the electronic tensile testing machine will inevitably produce a certain tilt, then the specific upper and lower clamps can not maintain the coaxiality. The test results have a great impact. The

4, the laboratory power supply voltage to be stable, can not be too much fluctuations back and forth, similar to home appliances, voltage fluctuations, electrical switches back and forth, it will lead to electrical failure. The range of control that typically fluctuates like electronic tensile testing machines should not exceed ±10% of the voltage. The

5. The corrosive medium around the electronic tensile testing machine is absolutely not acceptable. After all, the testing equipment is metal products. Once the electronic tensile testing machine is damaged, it will reduce the mechanical properties of metal materials such as strength, plasticity and toughness.

6. The laboratory where the electronic tensile testing machine is located must not be subject to vibration. If the vibration is generated during the test, the impact of the vibration on the test data will occur, and for a long period of time, the sensitivity of the sensor, encoder, etc. will be affected.